Composite materials are generally defined as materials produced from two or more constituent materials which have dissimilar chemical or physical properties which, in combination, join to create a material having properties unlike the individual elements. The use of composite materials is nothing new in the construction industry: indeed, some of the earliest recorded uses of composite materials include the use of a composite of straw and mud for wattle and daub-type building construction, dating back over 6000 years.

To this day, the use of composite materials in the construction industry is commonplace: One of the most ubiquitous composite materials used in construction is concrete, typically formed of aggregate in a cementitious matrix. However, concrete has previously been referred to as “the most destructive material on earth” - taking every stage of its production into consideration, concrete is said to be responsible for 4-8% of the world’s CO2, and it also has wide-ranging impact in terms of water use, and its tendency to add to the urban heat island effect.

With environmentalism and sustainability at the fore, and with existing infrastructure requiring rehabilitation or replacement, there is accordingly an increasing push towards a stronger and more sustainable future for the construction industry. In particular, there is a move towards replacing or upgrading more traditional construction materials, such as concrete, with modern alternatives which can offer advantages in terms of weight saving, ease of installation, corrosion resistance, durability, and/or resilience.

One example of a group of composite materials which is making rapid in-roads as a replacement for more traditional materials is fibre-reinforced polymer (FPRs). Fibre reinforced polymers typically comprise glass, carbon, aramid or other fibres set within a resinous matrix, and they offer an attractive alternative to the use of traditional steels in view of their corrosion resistance properties – a matter brought to the forefront by the Surfside condominium collapse in 2021, resulting from corrosion of steel rebars in the concrete structural support of the ground-level parking garage under the housing units - widely acknowledged to be the third-deadliest structural engineering failure in United States history.

Indeed, in recent years there have been a number of high-profile infrastructure projects that have made significant use of FPRs in high-corrosion environments – for example, the Jizan flood mitigation channel in Saudi Arabia, which uses 11,000 kilometres of glass-fibre reinforced polymer (GFRP) rebar to reinforce a 23 km long concrete channel, will be the world’s largest project to be constructed using GFRP composite rebar as its concrete reinforcement. This project is a significant turning point in the use of composite materials within the infrastructure sector and demonstrates their significant potential as an alternative to steel rebars for concrete reinforcement.

Even on a smaller scale, FRPs can provide significant benefits, offering the potential for lower impact construction, with lower weight components allowing for use of smaller, lighter cranes, or allowing for components to be pre-formed off site. For example, in 2021, Network Rail trialled the use of a fibre-reinforced polymer (FRP) rail footbridge at a test centre in Long Marston, Warwickshire. The bridge cost considerably less than traditional steel structures to produce and install, weighs less than half the amount of a traditional footbridge, and was produced in a modular fashion, allowing the bridge to be installed in a matter of days.

However, the growing use of composites in infrastructure and building project is not just limited to FRPs: a whole host of other composite materials are finding increasing use in various applications: For example, PTFE coated glass has become established as one of the highest quality architectural membranes for tensile fabric structures due to its high strength, inherent non-flammability, and low maintenance requirements. Biocomposites also offer promise, with the Pierre Chevet sports hall in Croissy-Beaubourg, France, demonstrating the possibilities for carbon-negative construction using ‘hempcrete’, made from hemp hurds, lime and water.

What are the challenges?

Well, there are a few: limited knowledge within the construction sector; restrictive standards or absence of available guidelines; lack of skills, and experience in the existing market; and lack of existing supply chains are just some. Sustainability, whilst one the one hand being a key driver for the use of these modern composites, is also a potential barrier, due to the limited end-of-life options for decommissioning composite infrastructure.

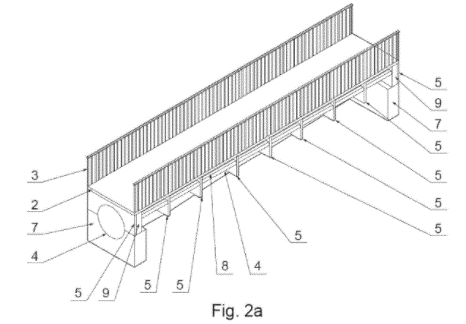

For some of these barriers, in particular, the sustainability barrier, further innovation may provide a solution. For example, Anmet, founded in 1998 by CEO Andrzej Adamcio, was originally started to provide manufacturing companies with solutions for metals recycling. However, since 2014, Anmet has focused on the growing need for solutions for recycling composite wind turbine blades at the end of their life spans, including the recycling of carbon fibre from wind turbine blade, as well as the physical repurposing of glass fibre wind turbine blades into components suitable for use in infrastructure project. The company’s 2020 patent application for a bridge span comprising wind turbine blades, was recently followed in October 2021 by the first installation of a pedestrian and bicycle footbridge in Poland.

For other barriers, more legislative effort may be required. Fortunately, this is an active topic in many countries – for example, in the US, the IMAGINE Act (Innovative Materials for America’s Growth and Infrastructure Newly Expanded), reintroduced on 24 March 2021 by U.S. Senators Sheldon Whitehouse and Susan Collins, aims to encourage research and deployment of innovative, advanced construction materials — including composites — in transportation and water infrastructure projects nationwide.

However, if we can overcome some, or all, of these challenges, composites could offer great opportunities for levelling up our global infrastructure. One group doing some thinking in this area is the American Society of Civil Engineers. Their Future World Vision project envisages what the cities of the future might look like – with floating cities being envisaged by 2040, and Smart/MegaCities in the more immediate future. For all of these future city concepts, modern composites seem to offer ideal solutions: resilient and corrosion-resistant materials for under-sea infrastructure; lightweight modular additions to existing infrastructure to scale our cities into MegaCities, or 5G-transparent construction materials allowing for greater ease of connection in Smart Cities of the future.

Whilst we can all agree that precisely what our future cities might look like isn’t 100% clear right now, what is clear is that composite materials appear to offer potential solutions that closely fit our global infrastructure needs, as well as our anticipated needs of the future. And as they say – the future is now.

Isobel is a Partner and Patent Attorney at Mewburn Ellis. She is an accomplished UK and European patent attorney whose technical expertise spans a wide range of technical fields in the mechanical engineering and materials engineering spaces. Her work extends across the full IP lifecycle: she has extensive experience in original drafting and patent prosecution work, as well as a keen interest in opposition and other contentious matters.

Email: isobel.stone@mewburn.com

-1.png)