Since their introduction into the America’s Cup boats in 2013, hydrofoils have become familiar to even the most casual of sailing fans. It’s hard not to be captivated by the wide-angle shots of these boats flying along above the water surface, propped up on seemingly comically thin struts. Whilst the latest America’s Cup boats are undeniably the vanguard of hydrofoils for racing yachts, their history goes much further back than this.

In this blog we take a look back at over 150 years of hydrofoiling and look towards the future for this technology.

The Early Pioneers

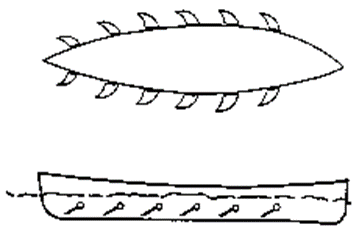

The origins of hydrofoils on vessels can be traced back to 1869, when Parisian Emmanuel Denis Fargot obtained a patent for his rowing boat incorporating hydrofoils on its sides and under-surface, which he declared ‘will have the effect of lifting it in the water and reducing the draught’.

Illustrations from Fargot’s patent application for his hydrofoil-equipped rowing boat.

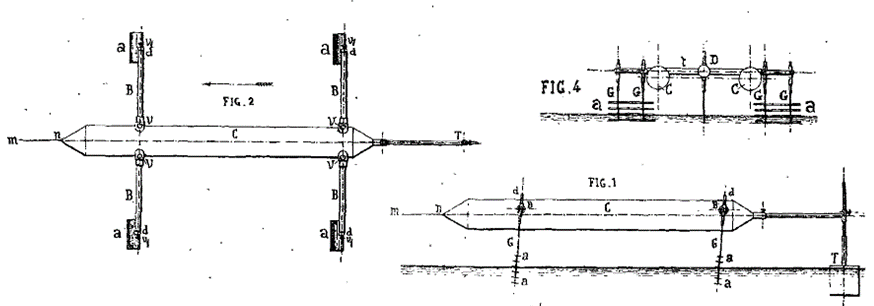

It’s unclear if Fargot ever reduced his patented rowing boat to practice, because it is not until 1898 that the next major progress is recorded, with revered Italian engineer and prolific patentee Enrico Forlanini (perhaps most famous for his airships) starting to develop an airscrew driven boat with a pair of ladder foils at the stern and bow. Forlanini knew that the lift generated by a foil was proportional to the square of the speed, and thus the foiling area required reduced as the vessel’s speed increased. The ladder foils – with a series of foils being the ‘rungs’ of the ladder – allowed Forlanini to achieve a decrease in foil area as the boat lifted further out of the water and its speed increased.

Schematics of Forlanini’s ladder-hydrofoil boat from his GB patent application GB190507603A.

By 1906 Forlanini was testing his craft on the waters of Lake Maggiore and had already filed a patent application for his invention. His craft reached a speed of 68 km/h, and by this point it’s fair to saythat hydrofoils were now attracting a fair amount of attention, in particular from aviation pioneers - after all, the same principles underlie both hydrofoils and aeroplane wings.

The Need for Speed

Although the potential benefits of hydrofoils extend much beyond the greater speeds obtainable, it was this speed that captured the imagination of the engineers working on them. Alexander Graeme Bell (of telephone fame) even turned his attention to hydrofoils, developing his HD-4 craft following a ride in Forlanini’s boat. The HD-4 initially reached a top speed of 87 km/h, following which the US Navy decided it was worth dipping their toes into – providing two 350 hp engines that allowed Bell’s creation to reach an eye-watering 114 km/h – a world marine speed record at the time!

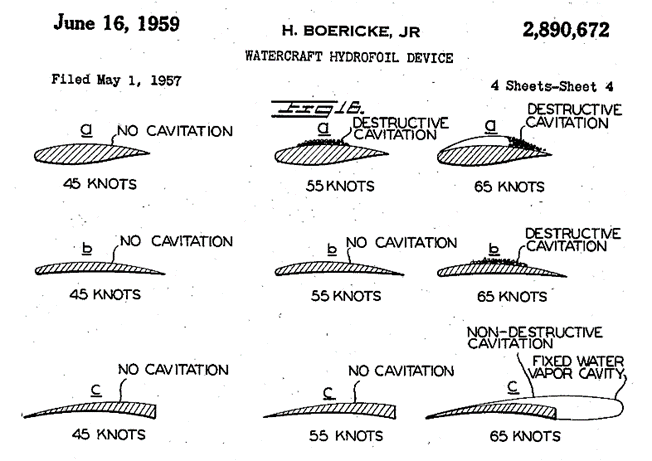

However, as those that tried to better Bell’s record would find, there was actually a limit to how fast a hydrofoiling vessel of the time could go. Much like with rapidly spinning propeller blades, as the speed of a foil moving through the water increases, the reduction in static pressure of the water above and behind the foil body is reduced below the vapour pressure of the water. This results in the formation of a vapour-filled cavity, which subsequently becomes re-pressurised as the foil moves further downstream. The re-pressurisation causes the cavity to collapse and generate a shock wave that is transmitted to the foil, causing it to deform and the lift generated to fall. Such cavitation begins to occur readily at speeds in excess of 110 km/h.

It wasn’t until supercavitating foils were developed that this speed limit could be overcome. These are designed to be able to create a cavity at or near the leading edge of the foil that then encapsulates the remainder of the foil downstream within the vapour and is substantially more stable than smaller cavities.

Illustrations from US patent application US2890672A illustrating the influence of their shape on cavitation effects at high speeds.

Branching out

Whilst ladder-style hydrofoils were popular in the early years of hydrofoiling, advances in both the understanding of hydrodynamics and materials have allowed substantial refinements and evolution in hydrofoil shape – gone are the ladder arrangements, and modern hydrofoils such as those used in the America’s Cup boats are capable of supporting the weight of five cars on a single foil about the size of your coffee table.

Using hydrofoils on sailing boats is not new – the earliest record of a hydrofoiling sailing boat was back in 1938, but it is here that the ability of hydrofoils to do more than just generate lift is perhaps clearest.

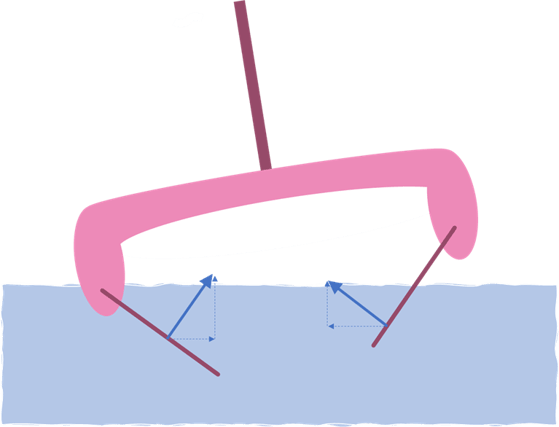

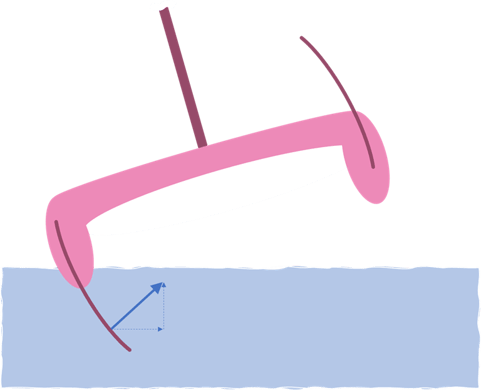

Surface-piercing hydrofoils, where two hydrofoils extend into the water in a ‘V’ shaped configuration allow heel in sailing to be counteracted, improving boat stability and controllability as well as speed. Meanwhile, ‘C’- and ‘S’-shaped foils can allow the balance of the horizontal and vertical components of the force generated by foil to be controlled by varying the amount of the foil submerged in the water, which in turn can allow the boat to sail closer to the wind when heading upwind and still generate significant lift and reduce drag when heading downwind at higher speeds.

A pair of surface-piercing hydrofoils on a catamaran. As the boat heels, the leeward foil is submerged further and its upper surface cants over and generates a greater righting force.

Flying into the future

Whilst hydrofoils have seen a boom in sailing boats, and indeed other wind-powered craft such as kitesurfs and windsurfs in recent years, their use in passenger and work boats has not made so much headway.

This is now changing. The increasing focus on emissions arising from the marine sector has prompted boatbuilders to start shifting towards electric propulsion, which is becoming increasingly feasible as battery and motor technology improves (see our previous blog on how the tide is turning for electric propulsion in the shipping industry). Just as with cars, range anxiety is real with electric boats and in order to make the most of the energy stored in the batteries of these electric boats, hydrofoils are being employed to reduce drag. Artemis already have a fully-electric workboat that is using their eFoiler® system (the subject of a handful of patent applications) featuring twin ‘T’-foils, which they claim can reduce energy costs by 70%. Candela, a Swedish electric boat outfit partnering with Polestar for their battery systems, claim to go one better, stating an 80% reduction in drag for their P-8 water taxi.

A pair of ‘C’-shaped hydrofoils on a catamaran. Each foil can be moved within its hull to alter the proportion of it exposed to the water, and thus the magnitude and direction of the force it generates.

Although it might be some time yet before hydrofoiling boats are in the majority, the trend of advancement of hydrofoils over the past 150 years does not show any sign of heaving to. Technological innovations in hydrofoiling arising in the high-tech world of yacht racing will hopefully continue to trickle down to the masses, and as the pressure to decarbonise our transport intensifies, we should be grabbing them with both hands.

Rob is a patent attorney in our engineering and ICT team. Rob has an MEng degree in Chemical Engineering from the University of Cambridge. His masters research project focussed on three-dimensional analysis of particle-size segregation within granular avalanches using magnetic resonance imaging. During his undergraduate studies, Rob spent time working for Proctor & Gamble within their Baby-Care R&D Group.

Email: rob.walker@mewburn.com

.png)